Products

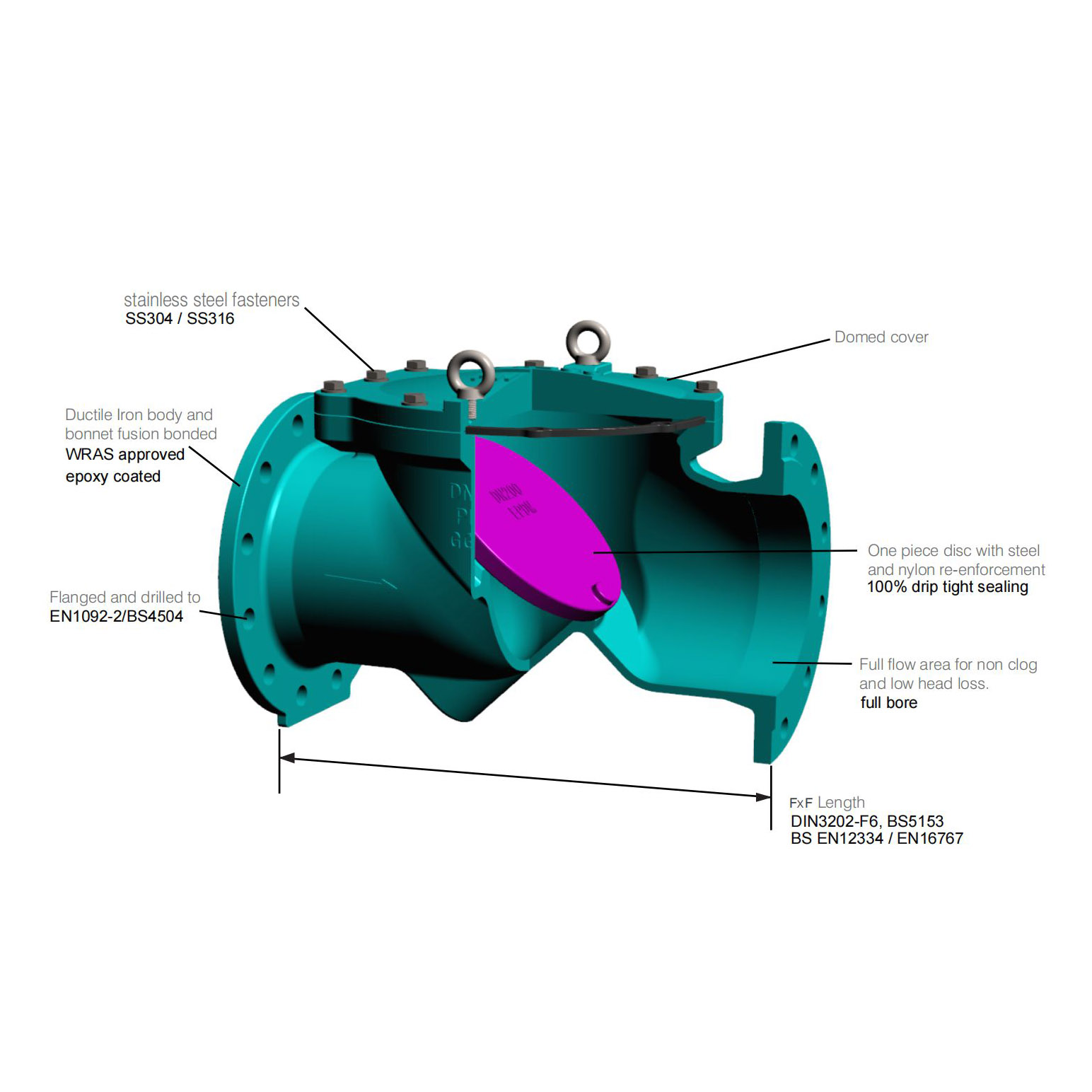

Rubber Flap Check Valve

Brief description:

- Rubber flap check valve,is designed to prevent reverse flow automatically.

- During system flow conditions, the movement of the fluid forces the disc to the open position allowing 100% un-restricted flow area through the valve.

- Under reverse flow conditions, the disc automatically returns to the closed position to prevent reverse flow.

- The valve is of the swing check type utilizing an angled seat and fully encapsulated, resilient disc.

- It is capable of handling a wide range of fluids including flows containing suspended solids.

Product Description

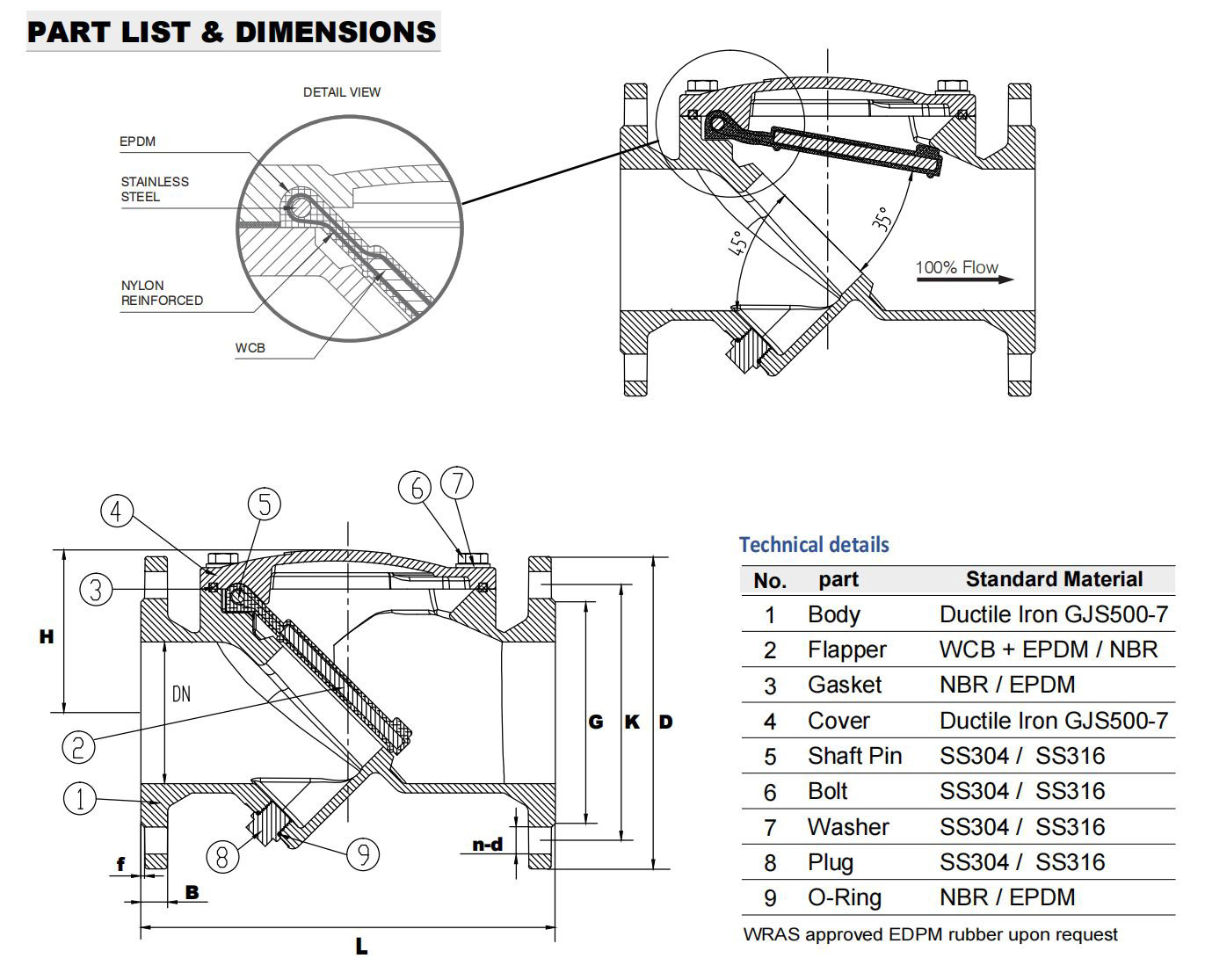

The rubber flap check valve is mainly composed of three main parts: valve body, Bonnet and rubber flap. The rubber flap is made of steel plate, steel rod and reinforced nylon cloth as the substrate, and the outer layer is covered with rubber. The service life of flap can reach 1 million times.

It is mainly applicable to the water supply and drainage system installed horizontally, and can be installed at the discharge of the pump to prevent backflow and water hammer from damaging the pump.

It can also be installed on the bypass pipe of the water inlet and outlet pipe of the reservoir to prevent the pool water from flowing back into the water supply system.

The check valve is generally suitable for cleaning media, and should not be used for media with solid particles and high viscosity.

Standards

▪ Hydraulic tests according to EN-12266-1, Class A

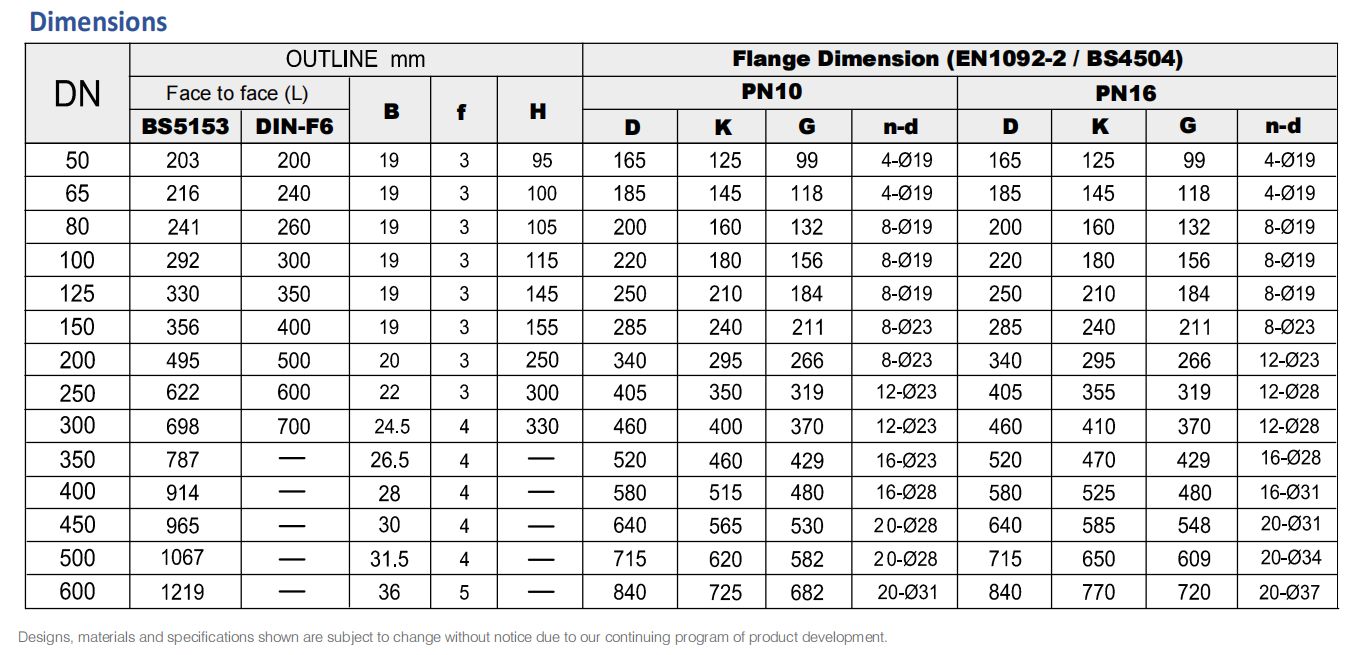

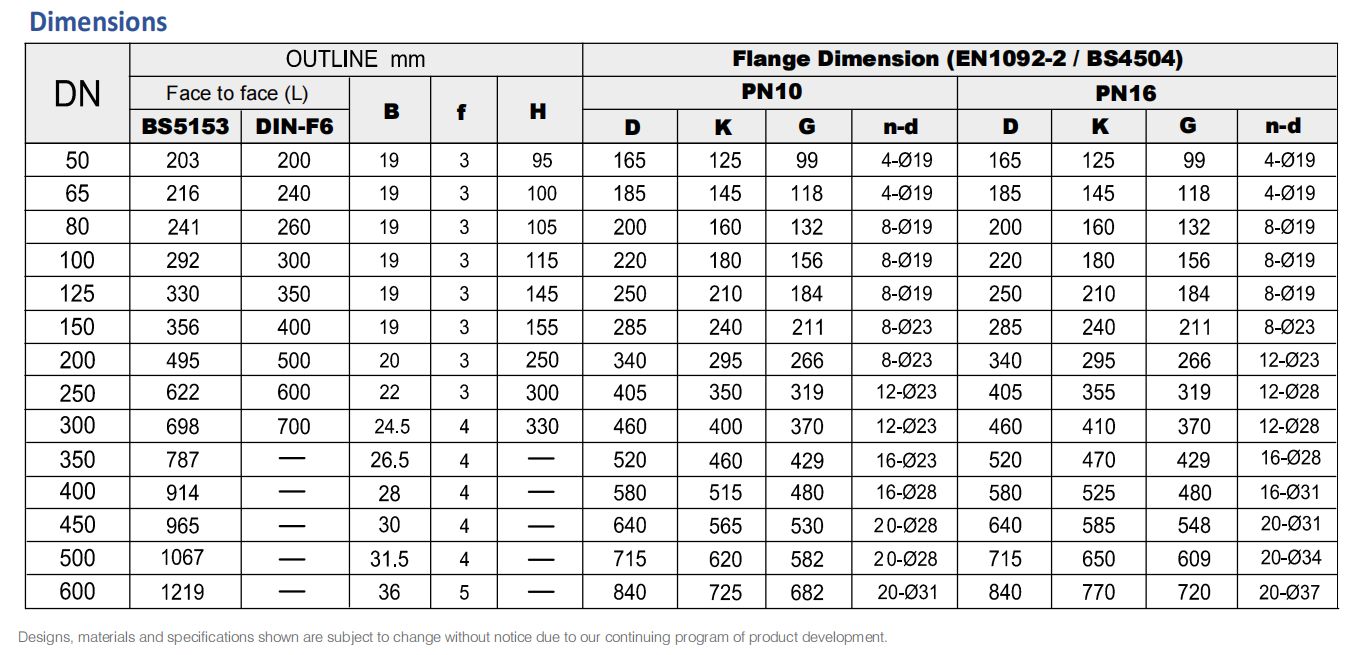

▪ Design: DIN3202-F6, BS5153, BS EN12334/EN16767

▪ Flanges to EN-1092-2, BS4504

Service Fields

▪ Potable water and neutral liquid applications

▪ Main transmission pipelines

▪ Irrigation system

▪ Fire fighting

▪ Pump stations

Main Features

▪ rubber seated, 100% sealing, zero leakage

▪ easily rubber lined for abrasion resistance

▪ 100% testing before packing and delivery

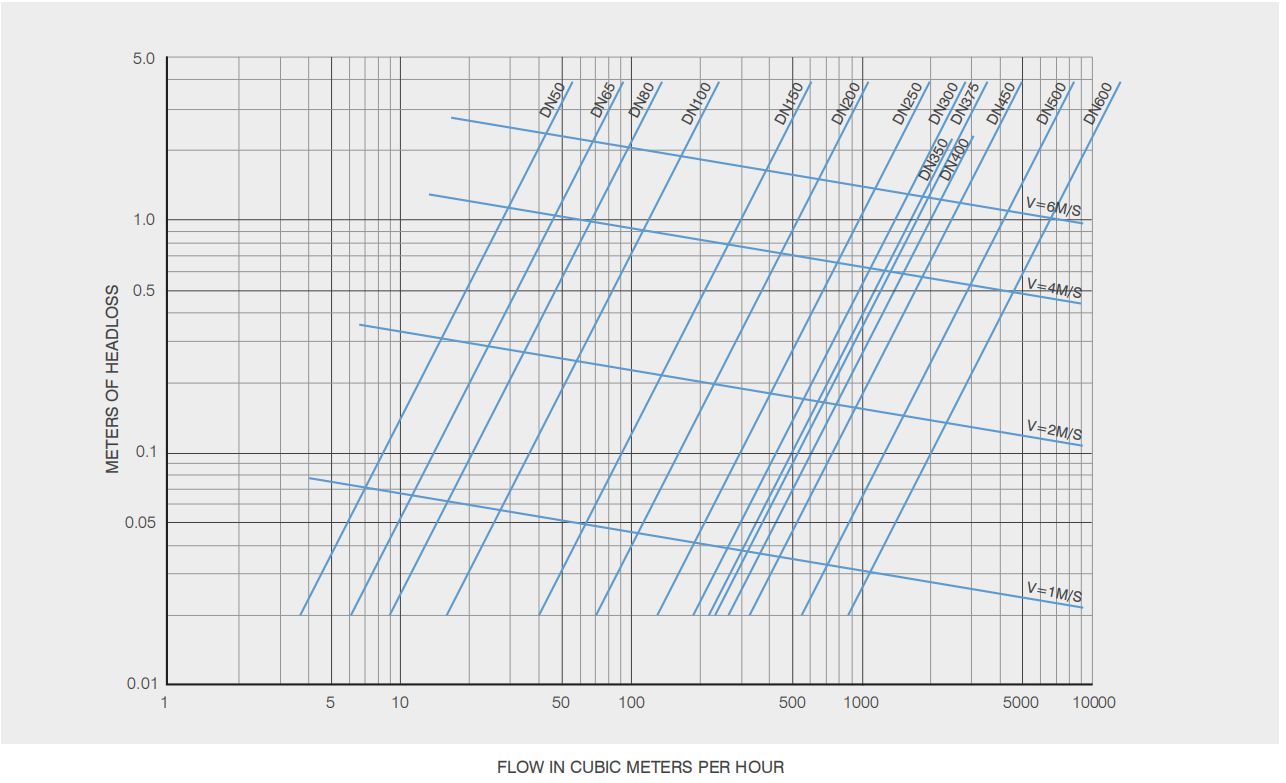

▪ 100% flow area, full waterway for low headloss

▪ Usually suitable for Horizontal installation

▪ one piece disc, special precision moulded EPDM

▪ internal steel re-enforcement disc for positive closure

▪ non slam, non clogging

▪ do not need counterweight

▪ lower power consumption due to lower headloss

▪ WRAS approved material for drinking water upon request.

Pressure Drop

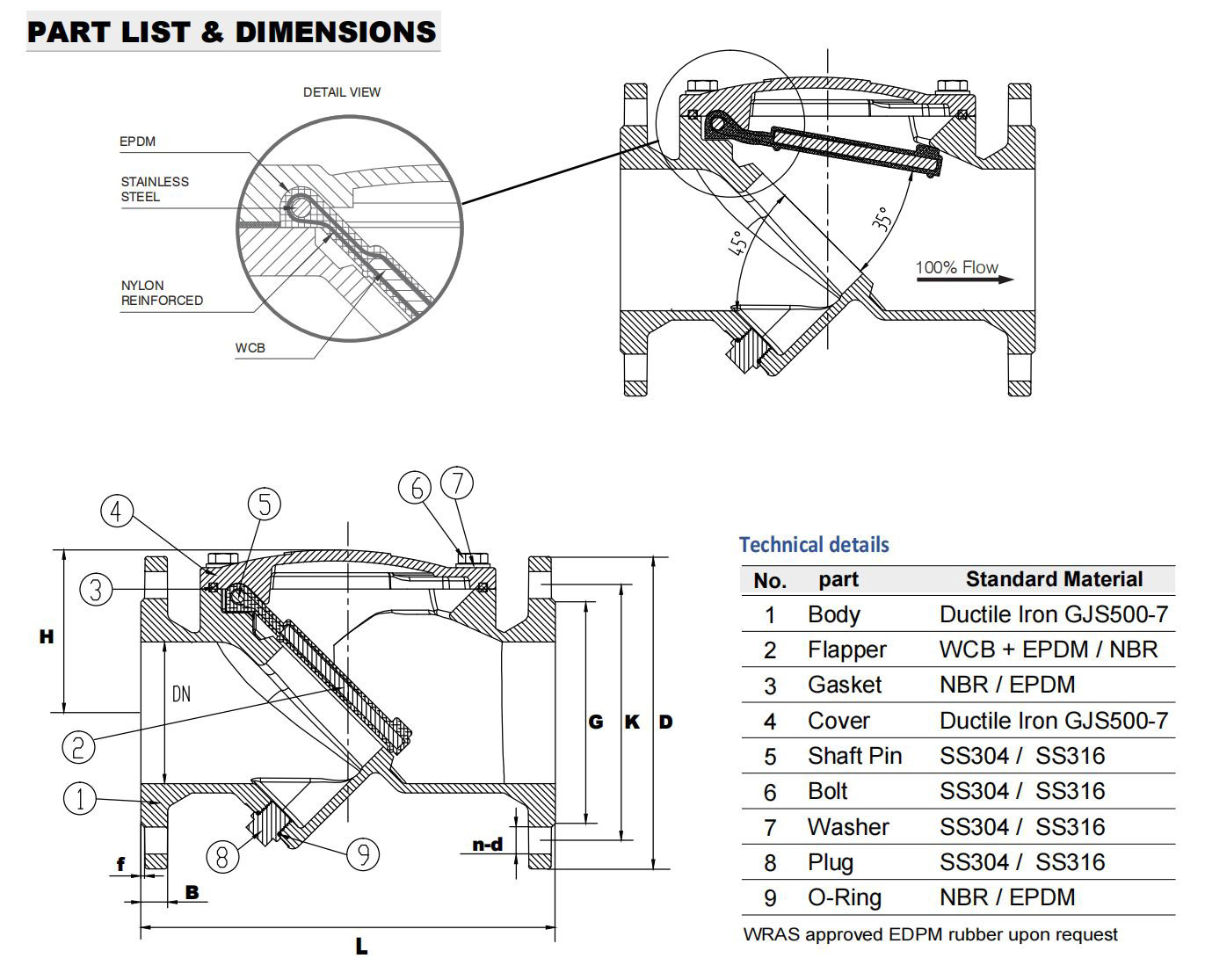

Technical details

|

No. |

Part |

Standard Material |

|

1 |

Body |

Ductile Iron GJS500-7 |

|

2 |

Flapper |

WCB+EPDM/NBR |

|

3 |

Gasket |

NBR/EPDM |

|

4 |

Cover |

Ductile Iron GJS500-7 |

|

5 |

Shaft Pin |

SS304/SS316 |

|

6 |

Bolt |

SS304/SS316 |

|

7 |

Washer |

SS304/SS316 |

|

8 |

Plug |

SS304/SS316 |

|

9 |

O-Ring |

NBR/EPDM |

Dimensions

Subscribe Now

An unmatched level of quality and serviceWe provide professional customized services for groups and individualsWe optimize our service by nsuring the lowest price.