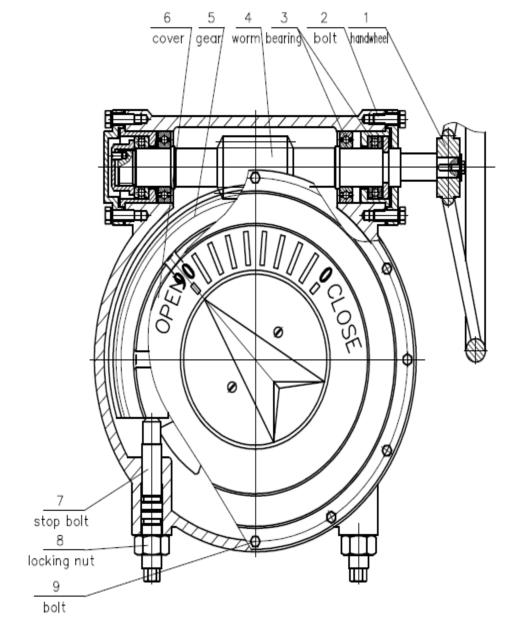

GEARBOX MAINTENANCE: A typical worm gear actuator is shown in the above Figure 1 and consists of a worm (4). The worm engages a segment gear (5). When the worm is turned, it drives the segment gear through 90° of rotation. The rotation of the segment gear is displayed by the top indicator. The gears are lubricated with grease in a ductile iron housing. The open and closed positions of the segment gear (5) are controlled by the end position limit bolts (7). The limit bolts can be adjusted by loosening the locking nut (8) and rotating the bolts (7).

Figure 1

The gearbox is factory lubricated and sealed. No regular maintenance is required.

★If in the condition of severe operation, the cover can be removed and inspect the friction parts. If need, the damaged parts should be replaced by contacting the supplier to provide the spare parts. The disassembly and assembly procedure should refer to the following instructions.

★All moving parts should be coated with grease. The grease should have an even and smooth consistency. If need, coat all moving parts with grease.

★Recommended grease type: 3# lithium based grease

GEARBOX LIMITING DEVICE ADJUSTMENT: Normally the gearbox is provided with factory-set properly restricting the valve in seated position. No field adjustment is necessary.

If the leakage is found from the valve seat during service, first check if the indicator of gearbox is to close(0°). If not, and the handwheel can no longer rotate. It should be because there are debris at the valve seat. If yes, it needs to adjust the limit bots of gearbox.

The adjustment method should be as per the below:

1.Adjust the closed end limit bolt by screwing out a certain length till the valve has no leakage and the opening end limit bolt should be screwed in the same length.

2.If the valve disc is over the valve seating position, the closed and opening end limit bolts should be adjusted in the reverse direction.

Please contact us for other details.

Zhengzhou City ZD Valve Co.Ltd

Post time: Feb-05-2024