Products

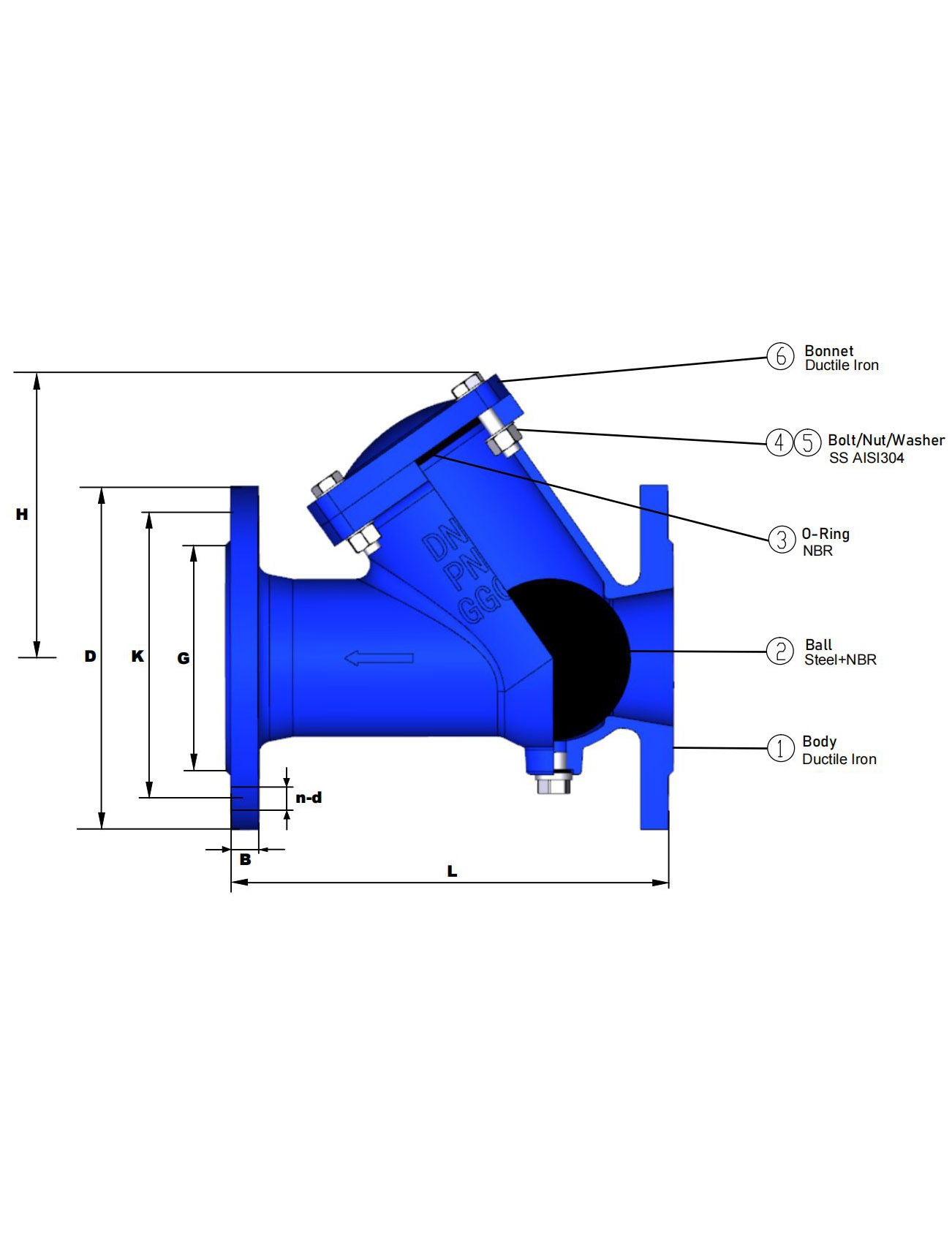

Ball type Non-Return Valve

Brief description:

Ball Check Valve is the main stream product type for the waste-water industry.

Internal and ball structure enables, non-stop functioning, self-cleaning and with full bore.

Operation is based on a free ball inside the body which is pushed by the pumped flow to the side cavity, allowing the liquid pass through.

When the pump stoped and the ball is no longer pushed aside, it drops back in the inlet port and prevents flow returns.

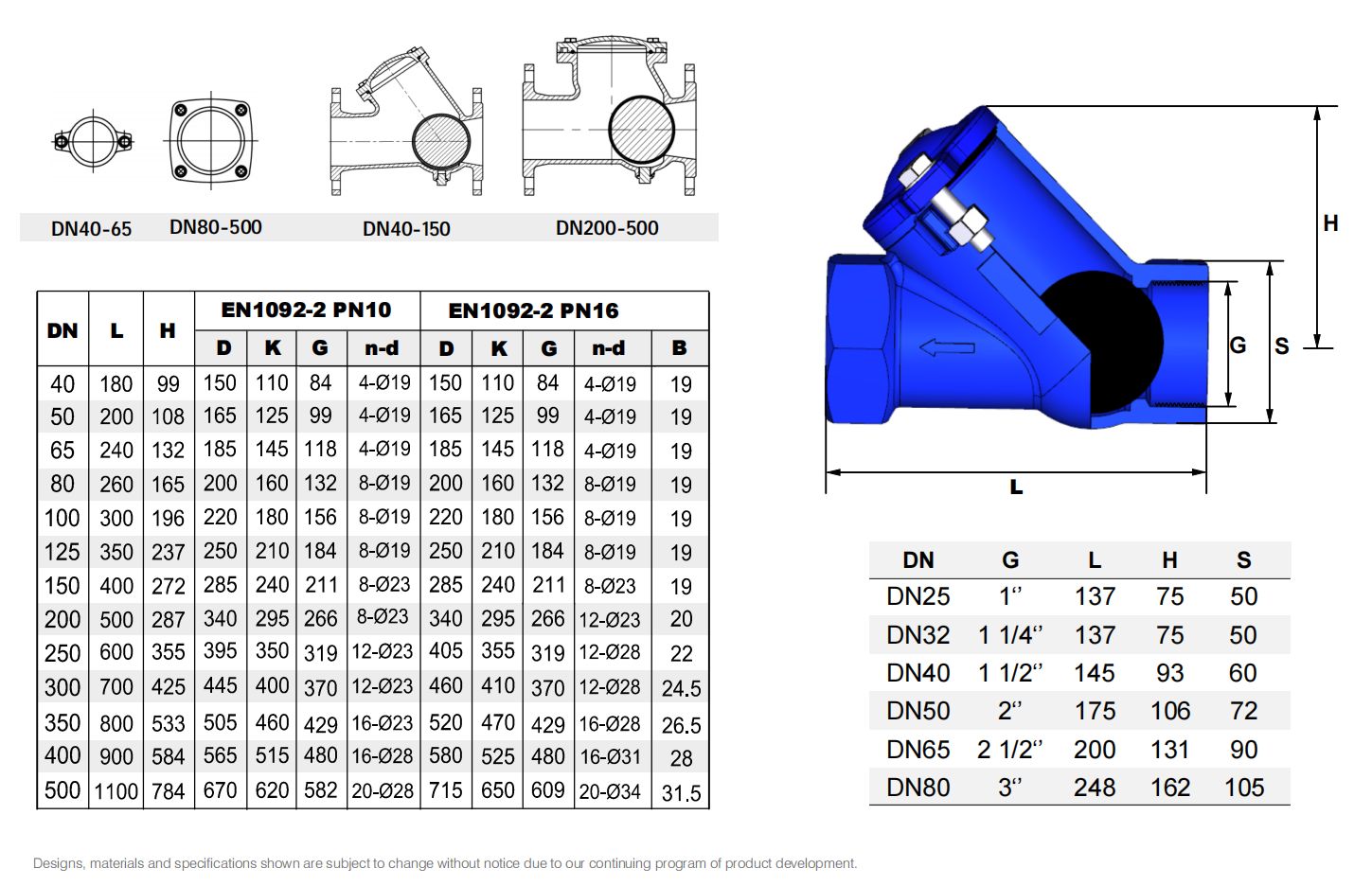

Ball check valves are available with flanges and internal threads.

Design Features

This type of valve is automatically opened and closed by the force generated by the flow of the medium itself in the pipeline. It is an automatic valve. It is applicable to industrial and domestic sewage pipe networks with high viscosity and suspended solids

Main Features

▪ Size range: up to DN400; Pressure range: up to 16bar

▪ Self-cleaning, no risk of impurities getting stuck on the ball.

▪ Silent closing, no water hammer to reduce the damage to the pipeline system during valve closing

▪ 100% testing before packing and delivery

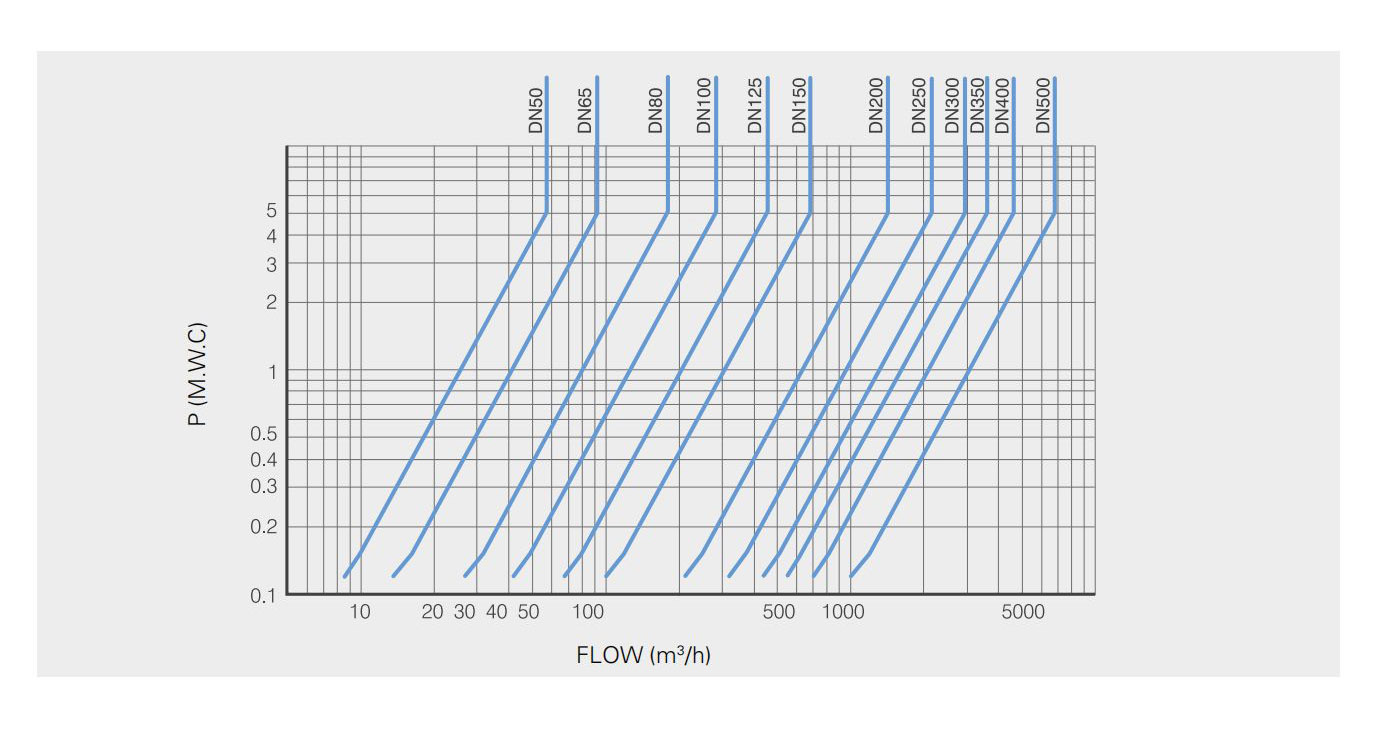

▪ full bore, 100% flow area, full waterway and low flow resistance for low headloss

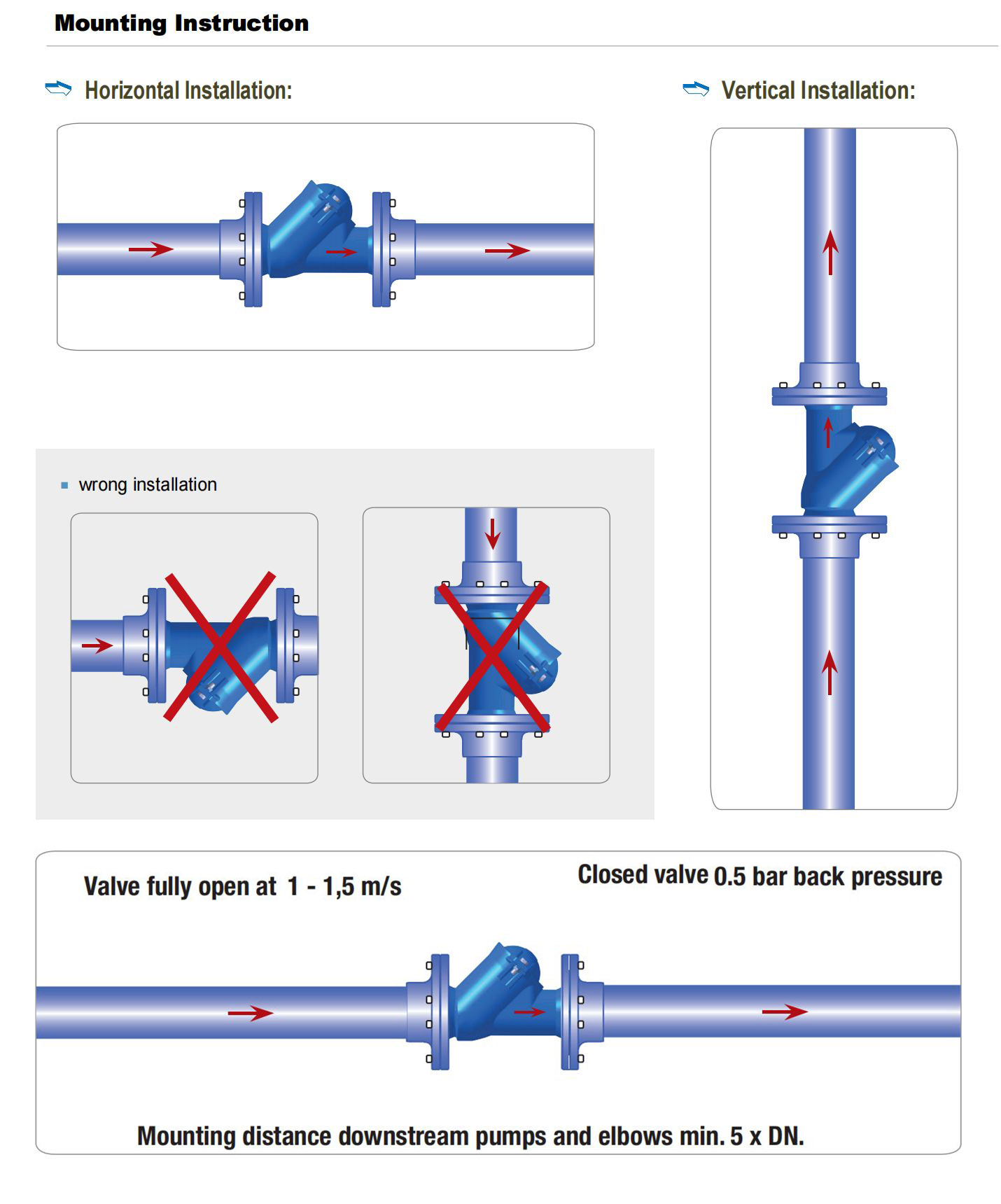

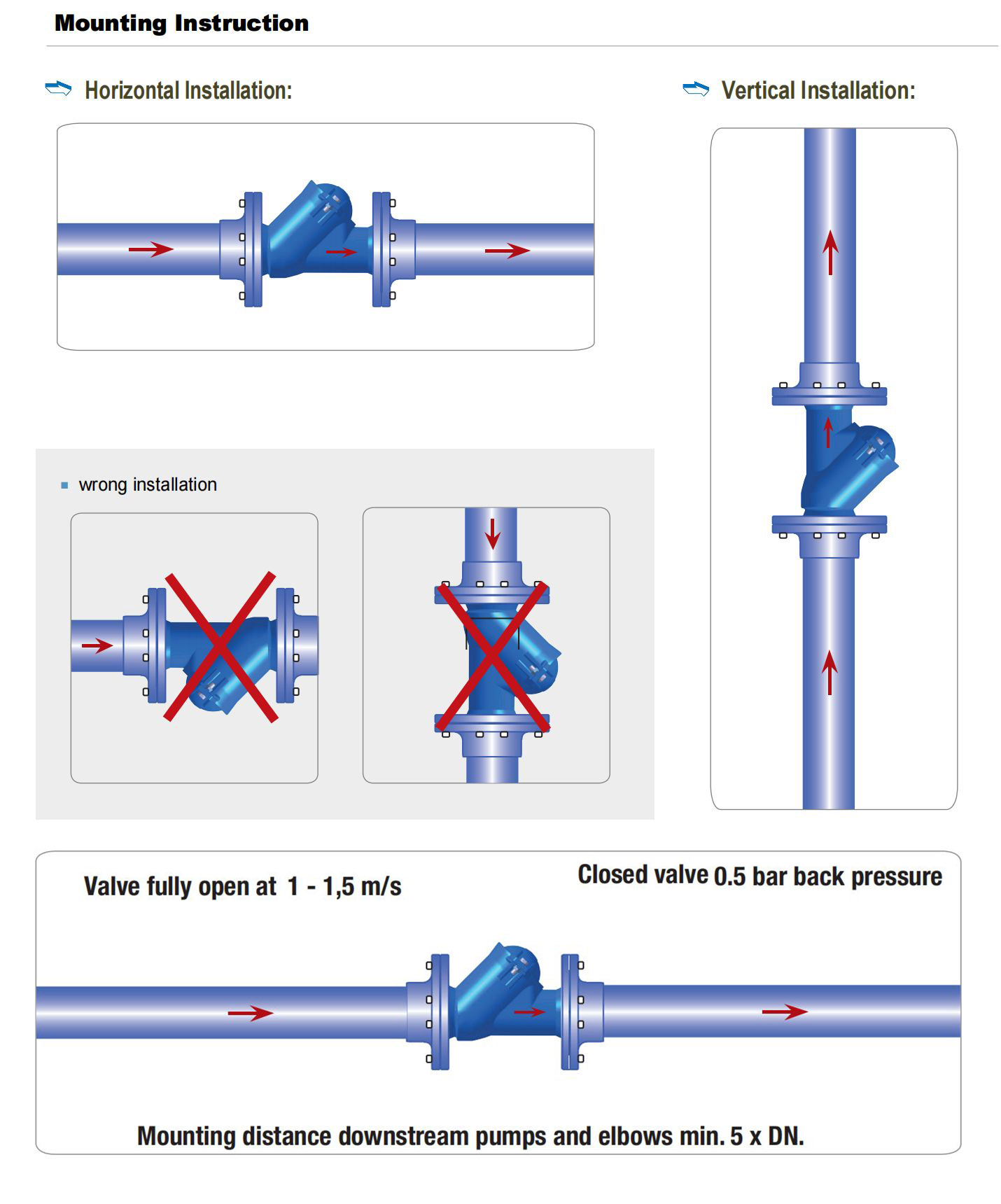

▪ suitable for Horizontal or vertical installation

▪ Compact design maintains easier installation.

▪ Light weight design for easy installation

▪ Self-cleaning sinking nitrile coated ball

▪ Eliminates the risk of impurities getting stuck on the ball.

▪ Low pressure drop

▪ The rubber ball adopts hollow steel ball, and is lined with rubber layer, which maintains certain elasticity to ensure valve sealing, and has sufficient strength.

▪ Cast ductile iron valve body with Inside and outside epoxy-coating.

▪ With long service life.

Standards

▪ Designed to EN12050-4 / EN 12334

▪ Hydraulic tests according to EN 12266-1

▪ Face-to-face: EN558 Table 2 series 48 (DIN3202-F6)

▪ Flange drilling to EN1092-2/BS4504, PN10/16

▪ Normally with double flange ends. Threaded ends (BSP inside screwed) are available for size DN80 and smaller.

▪ Minimum backpressure: 0.5bar

Service Fields

▪ wasterwater, sewage & mud.

▪ Neutral liquid, Non-potable water

▪ Industrial applications

▪ power plants and process industry

Specifications

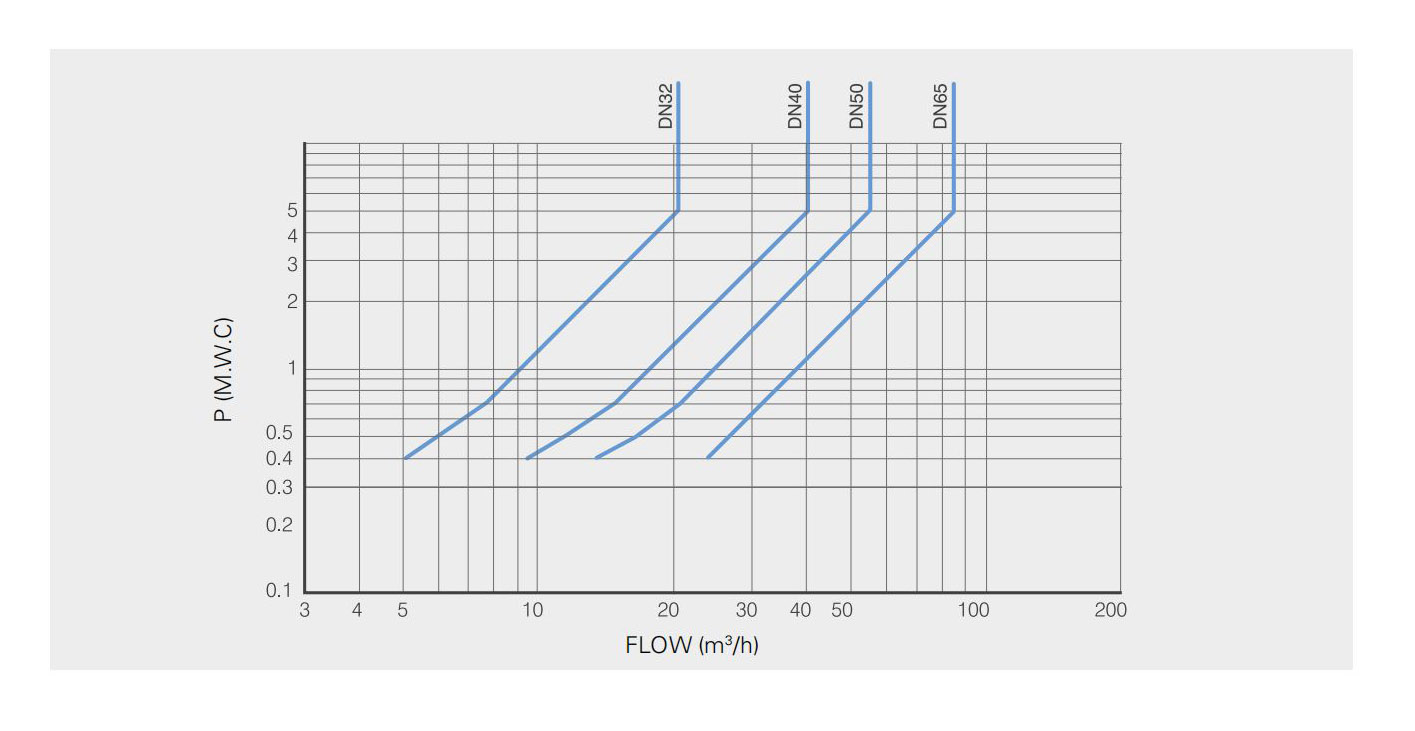

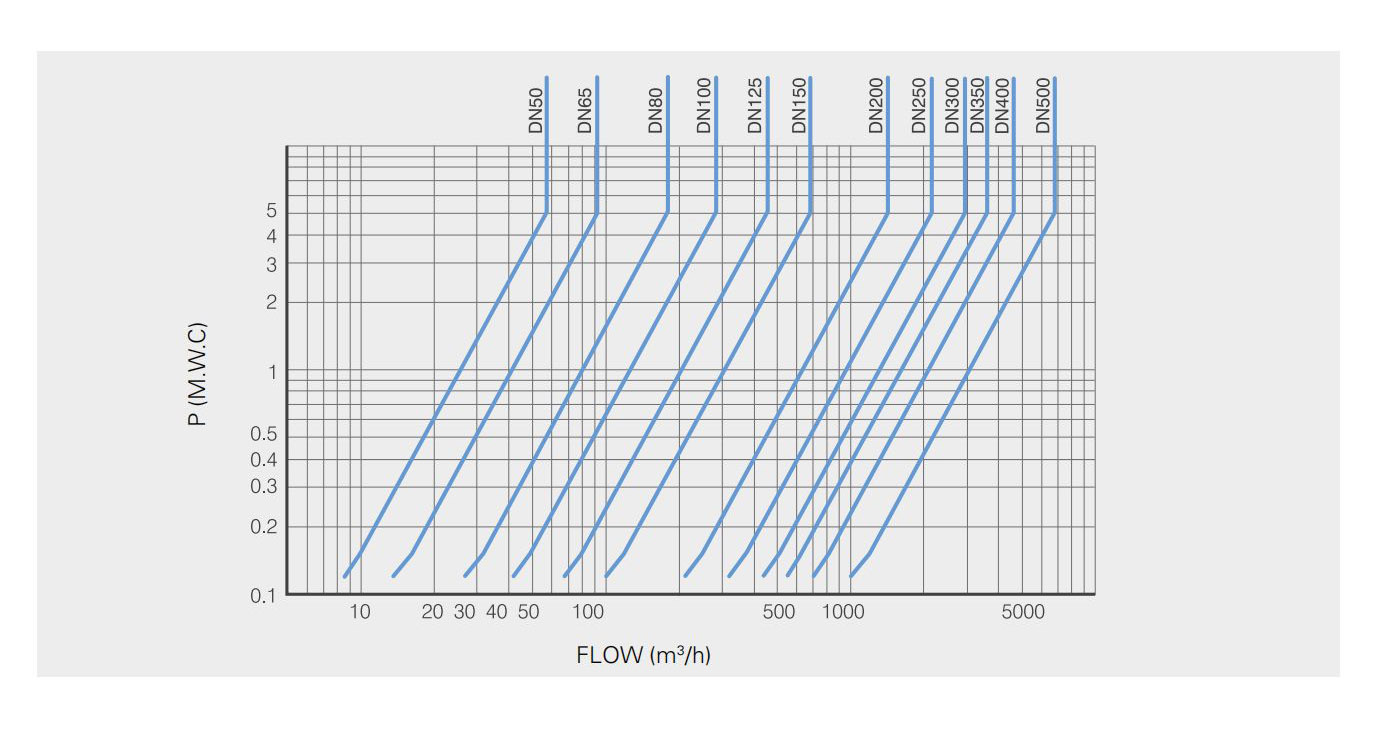

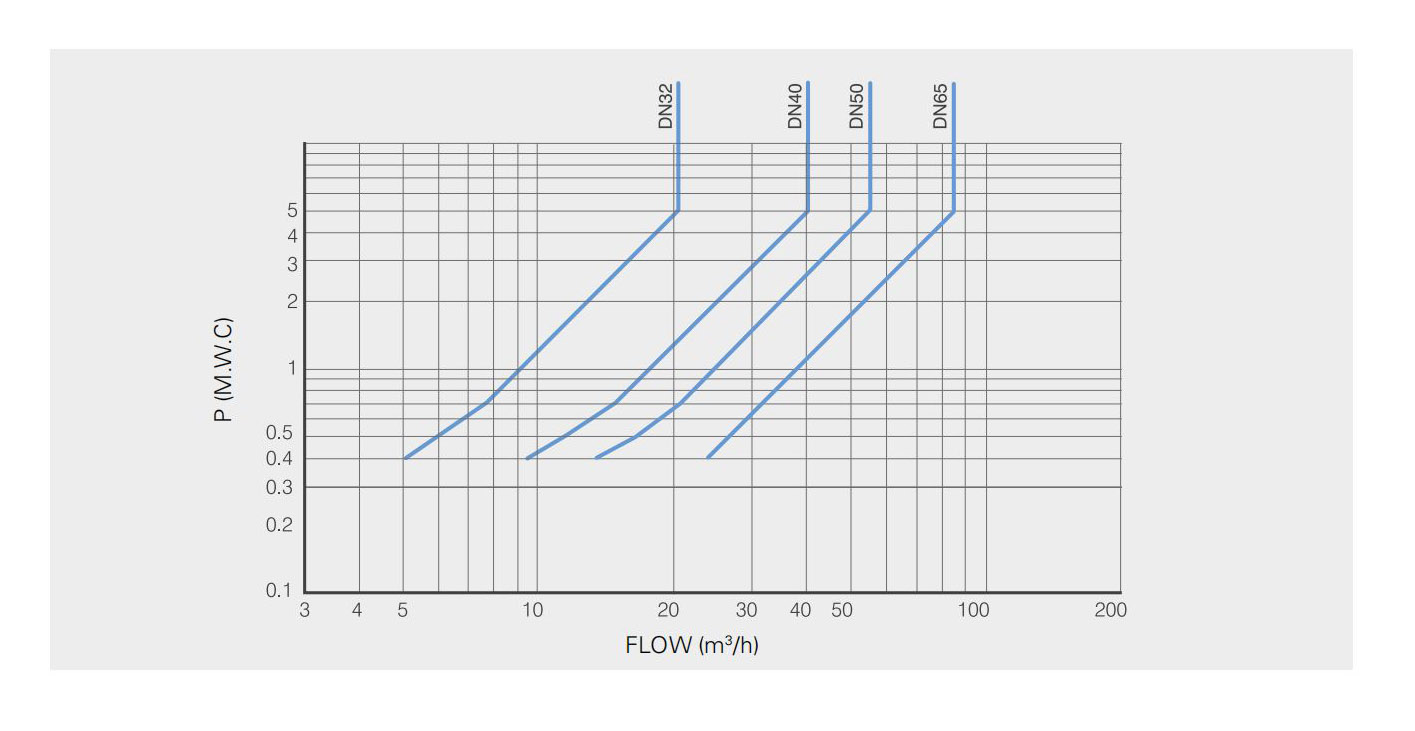

Pressure Drop

Flanged Ball Check Valve

Threaded Ball Check Valve

Subscribe Now

An unmatched level of quality and serviceWe provide professional customized services for groups and individualsWe optimize our service by nsuring the lowest price.