Products

Concentric Butterfly Valve

Brief description:

Used as line valves to throttle and cut off the service fluid.

Typically used for water, TSE water/treated waste water and sea water services

PRESSURE RATING: PN10, PN16, CLASS125/150

SIZE RANGE: DN50(2”) ~ DN4000(160”)

Suitable temperature: 0 ~ 200 ℃

SEAT MATERIAL: EPDM/NBR/VITON/SILICONE/PTFE/IIR

Design Features

Valve design to EN 593, API609 category A

Flange to EN 1092, ASME B16.1, ASME B16.5, AWWA C207

Face to face length to EN 558-1 series 20, API 609

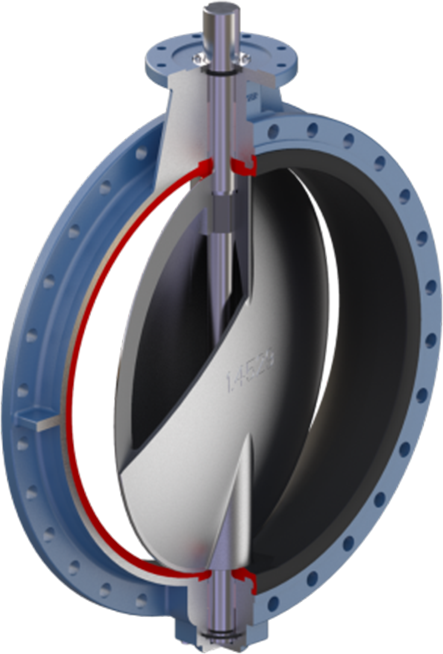

● Simple and compact structure, low operating torque. 90 ° turn to open quickly.

● Replaceable valve seat, with reliable & bidirectional sealing performance.

● The flow characteristics tend to be straight, with better adjustment performance.

● Self lubricating bearing in PTFE, al-bronze or stainless steel lined PTFE, with low friction coefficient and easy operation.

● ISO 5211 top flange to coupled with manual, electric or pneumatic etc all types of actuators.

● Multiple sealing design in shaft seal system, to ensure shaft no contact with service medium to achieve dry shaft.

● Stepped shaft design retained by a circlip to achieve blow-out proof shaft.

● The connection between shaft and disc is precisely processed to eliminate the linkage lag. And pinless two-piece shaft(one-piece available for request) design will ensure the valve shaft is completely isolated from the medium.

Used for corrosive medium, common shaft material could be used instead of high anti-corrosive material so as to reduce the production cost.

● The disc edge is processed with spherical surface and polished to ensure low operating torque.

Streamlined disc profile will ensure the max.flow performance to min. the pressure drop.

● The valve seat and body are positioned with single or double grooves to ensure no displacement and looseness during valve opening.

● The valve seat outside surface designed with a circular arc will accurate the positioning and be easy for replacement. No need of flange gasket during valve installation.

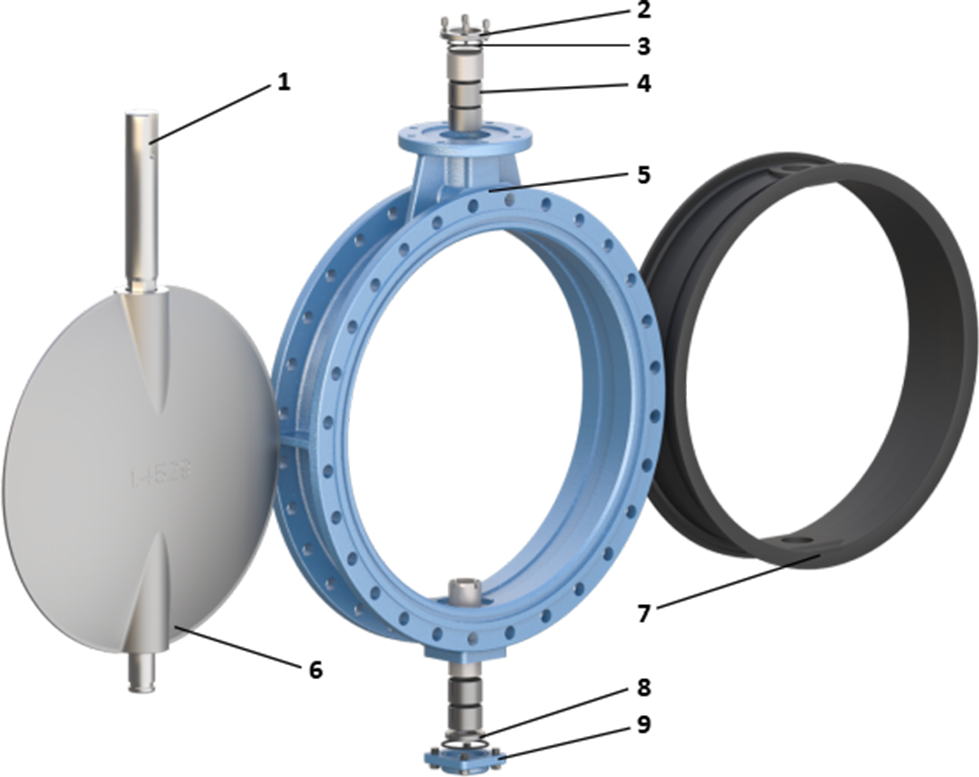

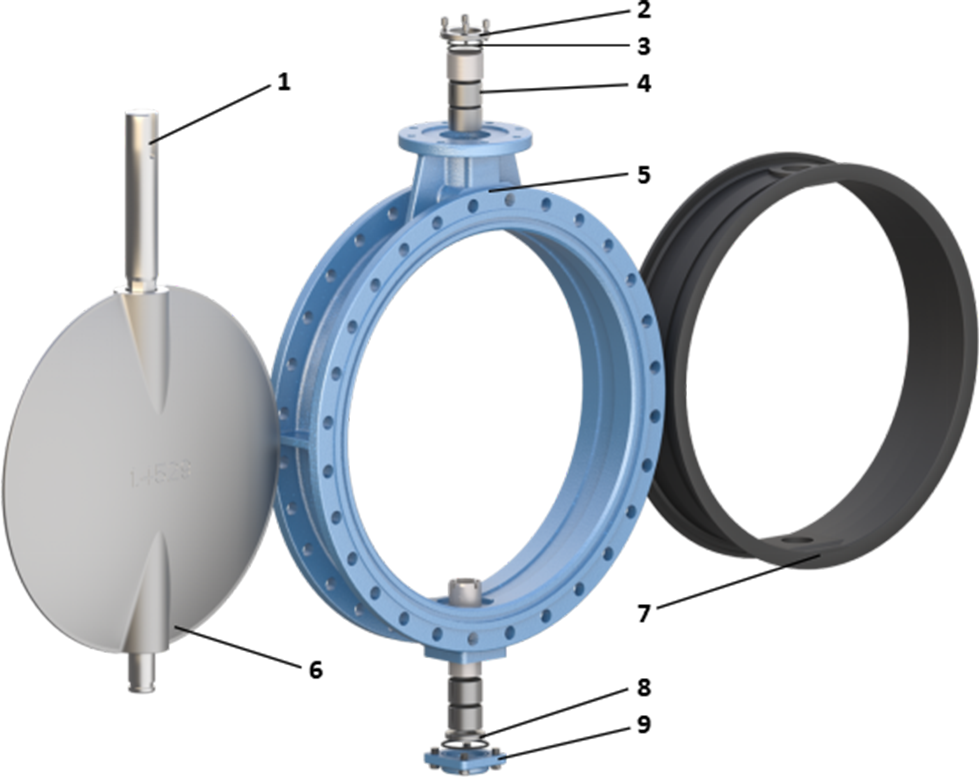

Materials of component

|

Part no |

Part name |

Material |

|

|

1 |

Valve shaft | Stainless steel/Duplex SS | SS410,SS431,17-4PH,1.4462,1.4507 etc. |

|

2 |

Packing cap | Carbon steel/Stainless steel | Q235,SS304 |

|

3 |

O ring | EPDM,NBR,FPM,AU etc. | |

|

4 |

Shaft bush | Bronze, PTFE, SS304/316 + PTFE | |

|

5 |

Valve body | Ductile iron | GJS400-15,GJS500-7,65-45-12 |

| Carbon steel | WCB | ||

| Stainless steel | CF8, CF8M,CF3M | ||

|

6 |

Valve disc | Ductile iron | GJS400-15,GJS500-7,65-45-12 |

| Stainless steel/Duplex SS | CF8, CF8M,CF3M,2205,2207, 4A, 5A | ||

| Al-bronze | C954,C955,C958 | ||

|

7 |

Valve seat | EPDM,NBR,FPM,AU etc. | |

|

8 |

Circlip | Carbon steel/Stainless steel | S235,SS304 |

|

9 |

End cover | Same to valve body | |

Note: The material will be designed and selected according to the actual working conditions or client’s special requirements.

Coating: epoxy/rylsan coating, total average thickness 300 micron

Pressure test to EN12266-1/API598:

Leakage rate: Class A (Zero leakage) in both direction; 100% testing before delivery

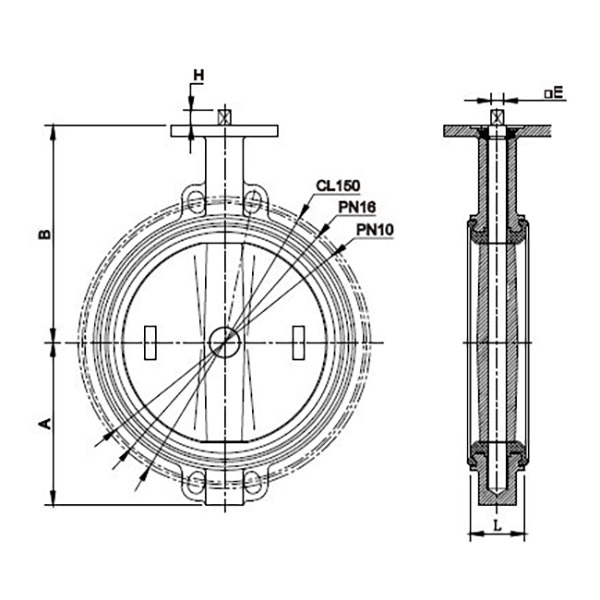

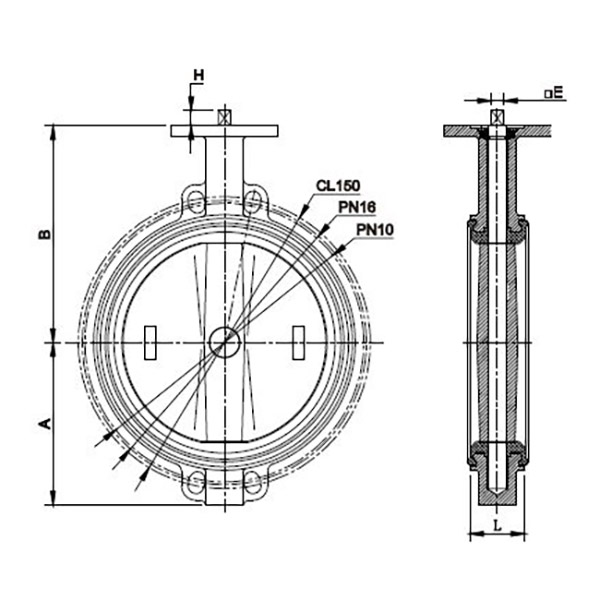

Dimensions

Dimensions for wafer & lug type

|

Size |

A |

B |

L |

H |

□E |

ISO 5211 top flange |

|

50 |

61 |

141 |

43 |

13 |

11 |

F07 |

|

65 |

72 |

153 |

46 |

23 |

11 |

F07 |

|

80 |

87 |

161 |

46 |

17 |

14 |

F07 |

|

100 |

106 |

179 |

52 |

17 |

14 |

F07 |

|

125 |

123 |

193 |

56 |

17 |

14 |

F07 |

|

150 |

137 |

204 |

56 |

20 |

17 |

F07 |

|

200 |

174 |

247 |

60 |

20 |

17 |

F10 |

|

250 |

209 |

280 |

68 |

26 |

22 |

F10 |

|

300 |

253 |

324 |

78 |

26 |

22 |

F10 |

|

350 |

267 |

338 |

78 |

32 |

22 |

F12 |

|

400 |

315 |

400 |

102 |

32 |

27 |

F14 |

|

450 |

315 |

425 |

114 |

32 |

27 |

F14 |

|

500 |

363 |

485 |

127 |

43 |

36 |

F14 |

|

600 |

459 |

565 |

154 |

43 |

36 |

F16 |

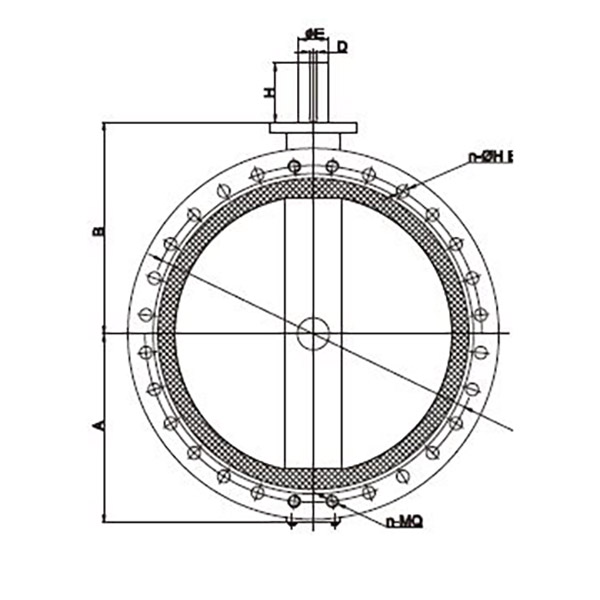

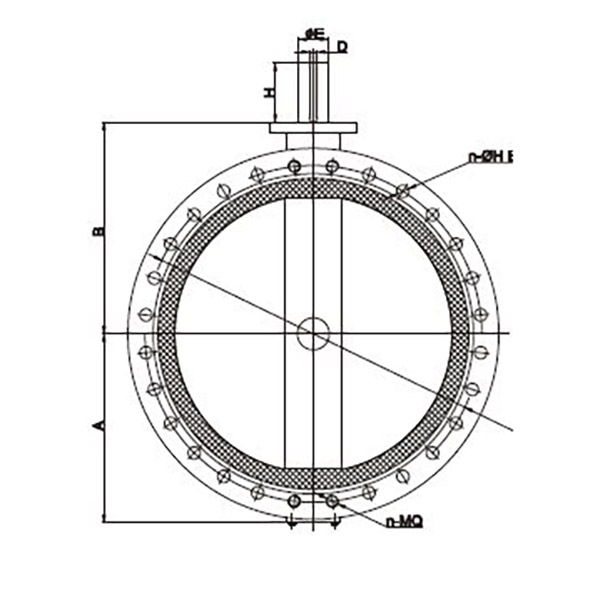

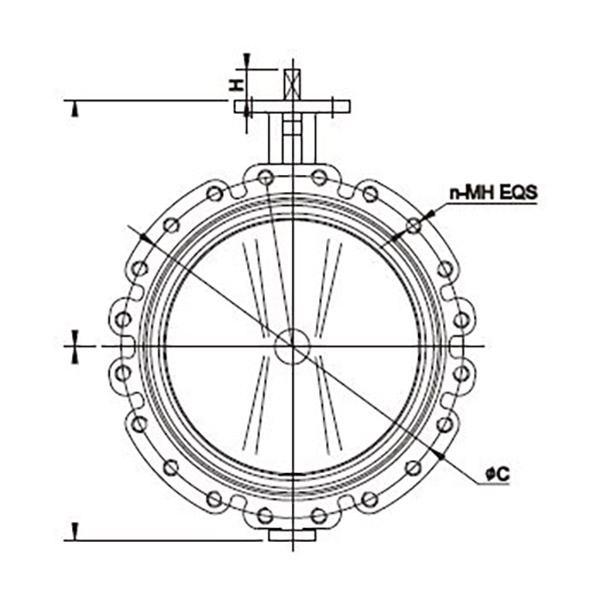

Dimensions for flange type

|

Size |

A |

B |

L |

H |

ΦE |

ISO 5211 top flange |

|

450 |

359 |

400 |

114 |

70 |

38 |

F14/F16 |

|

500 |

397 |

440 |

127 |

70 |

44 |

F14/F16 |

|

600 |

467 |

525 |

154 |

70 |

45 |

F16 |

|

700 |

507 |

629 |

165 |

90 |

65 |

F25 |

|

800 |

556 |

666 |

190 |

90 |

65 |

F25 |

|

900 |

612 |

720 |

203 |

100 |

75 |

F25 |

|

1000 |

670 |

750 |

216 |

120 |

85 |

F30 |

|

1100 |

778 |

865 |

254 |

120 |

85 |

F30 |

|

1200 |

805 |

876 |

254 |

130 |

105 |

F30 |

|

1300 |

940 |

930 |

279 |

150 |

120 |

F35 |

|

1400 |

965 |

1000 |

279 |

150 |

120 |

F35 |

|

1500 |

1000 |

1050 |

300 |

200 |

140 |

F40 |

Subscribe Now

An unmatched level of quality and serviceWe provide professional customized services for groups and individualsWe optimize our service by nsuring the lowest price.